Comprehensive Solutions for Semiconductor Obsolescence

Flip Electronics Manufacturing Services

Addressing Obsolescence Challenges in the Semiconductor Industry

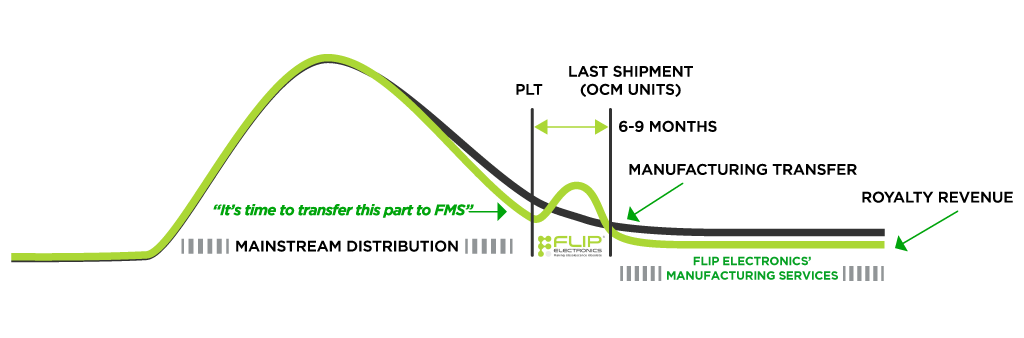

Obsolescence remains a persistent challenge in the semiconductor industry. Rapid technological advancements, industry consolidation, and the adoption of advanced fabrication processes often result in the discontinuation of vital legacy components. This exposes original equipment manufacturers (OEMs) in sectors such as automotive, industrial, networking, aerospace, and defense to supply chain risks, as their products often have lifecycles that extend beyond those of the semiconductors they depend on. Flip Electronics Manufacturing Services (FMS) provides innovative, reliable, and customer-focused solutions to bridge this lifecycle gap, ensuring a consistent supply of essential components.

FMS is a cornerstone of Flip Electronics’ mission to deliver exceptional value through authorized distribution, extended-life manufacturing, and comprehensive end-of-life (EOL) planning and mitigation strategies. By leveraging strategic partnerships with original component manufacturers (OCM), FMS empowers OEMs to maintain production continuity, avoid costly redesigns, and address the unique challenges of their supply chains.

A Strategic Extension of Flip Electronics

FMS builds on Flip Electronics’ expertise in sourcing hard-to-find semiconductor components. While Flip Electronics supports customers by procuring finished goods, FMS secures wafers, die, and intellectual property to ensure long-term product availability. This dual approach enables Flip Electronics and FMS to offer a seamless, end-to-end solution for managing product lifecycles. From Bill of Materials (BOM) management to navigating EOL challenges, FMS provides tailored services that give OEMs greater control over their supply chains.

The FMS Mission

Flip Electronics Manufacturing Services is dedicated to bridging the gap between OEM product lifecycles and semiconductor availability, ensuring uninterrupted production for customers. By collaborating closely with original component manufacturers, FMS extends manufacturing processes to produce electronic components that are fully compatible in form, fit, and function with the original designs. Unlike emulations or substitutes, FMS delivers genuine 1:1 drop-in replacements, authorized and licensed by the original manufacturer. These components adhere to the original datasheet specifications, often eliminating the need for costly requalification processes.

View All PCNs

VIEW PCNs

View all Flip Electronics Manufacturing Inventory

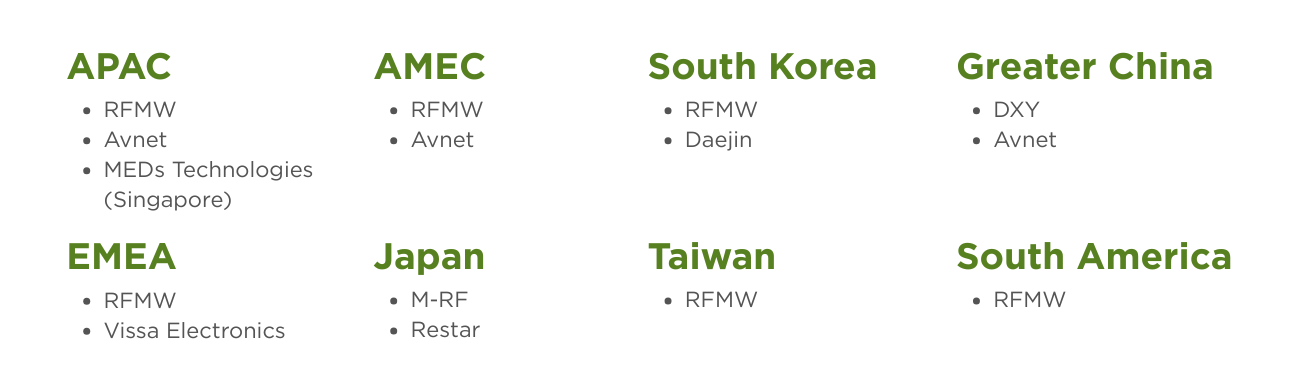

APAC

- RFMW

- Avnet

- MEDs Technologies (Singapore)

EMEA

- RFMW

- Vissa

AMEC

- RFMW

- Avnet

AMEC

- RFMW

- Avnet

South America

- RFMW

South Korea

- RFMW

- Daejin

Taiwan

- RFMW

Greater China

- DXY

- Avnet

Japan

- M-RF

- Restar

Contact Flip Electronics Manufacturing Services

To learn more about Flip Electronics Manufacturing Services, please send your inquiry to [email protected] or contact your Flip Electronics sales representative directly.

Tackling Mismatched Lifecycles

The lifecycles of electronic components often do not align with those of end products, particularly in long-lifecycle industries like automotive, aerospace, and defense. As OCMs streamline their portfolios to focus on newer technologies, an increasing number of semiconductors reach EOL status, shortening their average lifecycle duration. This mismatch creates significant challenges for OEMs, including:

- Sourcing Difficulties: Finding reliable and authorized sources for discontinued electronic components.

- Redesign Costs: Modifying products to accommodate alternative electronic components.

- Qualification Hurdles: Validating new electronic components to ensure compatibility and performance.

FMS addresses these challenges by offering extended semiconductor manufacturing services that ensure the continued availability of EOL components. Whether supporting high-value, low-volume orders or managing large-scale production of standard parts, FMS delivers customized solutions tailored to each customer’s needs.

Proven Expertise and Reliability for Obsolescence Management Solutions

With years of experience and millions of electronic components successfully delivered, Flip Electronics Manufacturing Services has established itself as a trusted leader in extended-life semiconductor manufacturing. Its efficient and economical business model enables OEMs to address lifecycle gaps and manage obsolescence challenges with ease. By partnering with FMS, both OEMs and original component manufacturers can focus on their core competencies while ensuring the continued production of long-lifecycle products.

Delivering Exceptional Value to OCMs and OEMs

Flip Electronics Manufacturing Services provides significant benefits to both OCMs and OEMs:

- For Original Component Manufacturers: By outsourcing the production of mature products, manufacturers can allocate resources to developing next-generation technologies while continuing to support customers who rely on legacy components. This ensures a balance between innovation and customer satisfaction.

- For OEMs: FMS guarantees a reliable, cost-effective supply of components that are identical in form, fit, and function to the original devices. This eliminates the need for expensive redesigns or requalification, saving time and resources while maintaining product integrity.

The Flip Electronics Manufacturing Services Advantage:

WIN-WIN-WIN

WIN for the customer - FMS guarantees a reliable, cost-effective supply of components that are identical in form, fit, and function to the original devices. This eliminates the need for expensive redesigns or requalification, saving time and resources while maintaining product integrity.

FMS mitigates and oftentimes eliminates any:

• Unplanned product decisions

• Product redesigns or requalifications

• Impact on customer base

• Component last time buys (LTBs)

• Extending the life of the device to meet the entire lifecycle of the end application

• All while meeting the original manufacturer datasheet as a complete drop-in replacement with no change to form or function

WIN for the OCM: By outsourcing the production of mature products, manufacturers can allocate resources to developing next-generation technologies while continuing to support customers who rely on legacy components. This ensures a balance between innovation and customer satisfaction.

• Customer Satisfaction

• Resource maximization

• Allow concentration on the next-generation electronic components without placing their customer in a compromised position

WIN for FMS:

• Strengthens its position as a trusted leader in extended semiconductor manufacturing, delivering tailored solutions that address obsolescence challenges.

Learn more about Flip Electronics Manufacturing Services

To learn more about Flip Electronics Manufacturing Services, please send your inquiry to [email protected] or contact your Flip Electronics sales representative directly.

Flip Electronics Manufacturing Services Leadership Team

Duker Dapper

Vice President & General Manager

Duker Dapper, a seasoned semiconductor industry leader, founded Resurgent Semiconductor, now Flip Electronics Manufacturing Services, to extend the lifecycle of legacy semiconductor components, leveraging over three decades of experience in engineering, operations, and business unit leadership. He launched his career at Cypress Semiconductor, steadily rising through the ranks by delivering results and building high-performance teams. His visionary leadership culminated in the successful acquisition of Resurgent by Flip Electronics in January 2023. Today, Dapper serves as General Manager of Flip Electronics Manufacturing Services, where he continues to drive solutions that keep critical technologies in production and help customers stay ahead of obsolescence.

Adam Mold

Director of Business Development

Adam serves as the Director of Business Development for Flip Electronics Manufacturing Services, while also managing several of Flip's key authorized suppliers. With over 25 years of global experience in the electronics components industry, Adam brings extensive expertise in both distribution and manufacturing. He spent more than two decades at Future Electronics in Europe and the Americas, leading Marketing Business Units and overseeing Focus Suppliers. For the past three years, he held the role of Senior Director of Global Distribution Marketing at Infineon Technologies within the IoT and edge AI-focused Connected Secure Systems Division.

Thomas Skarbek

Director of Sales Operations

Thomas Skarbek, Director of Sales Operations at Flip Electronics Manufacturing Services, has more than 30 years of experience in the semiconductor industry. He speaks to the industry regularly on topics of product obsolescence management and risk mitigation. Skarbek has also served as a member of the Anti-Counterfeiting Task Force (ACTF) of the Semiconductor Industry Association (SIA), which worked on the language incorporated in the National Defense Authorization Act. He holds a Bachelor's of Science in Electrical Engineering from University of Massachusetts, Lowell.

Nonie Estepa

Product Engineering Sr Manager

Antonio "Nonie" Estepa started his 30+ years of semiconductor experience with Texas Instruments (Philippines) in July 1993 as a test equipment technician and became a Product Engineer in June 1998. Nonie joined Cypress Semiconductor (Philippines) in July 1998 as a staff product engineer. He progressed through roles of increasing responsibility in engineering and operations management for 26+ years with Cypress Semiconductor and Infineon. In November 2024, Nonie became a Senior Product Engineering Manager of Flip Electronics Manufacturing Services.

David Drezek

Product Manager

David Drezek started his career in the electronics industry as a warehouse manager for a small contract manufacturer in MA. He went on to work for Solectron, a worldwide CM (now Flextronics), where he worked over a span of 23 years as a materials program manager, production control manager, planning manager, and program manager. David is currently the Product Manager for Flip Electronics Manufacturing Services.